The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

Table of ContentsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The Motorcycle Parts New Zealand Specialists DiariesThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsRumored Buzz on Motorcycle Parts New Zealand SpecialistsSome Known Factual Statements About Motorcycle Parts New Zealand Specialists Everything about Motorcycle Parts New Zealand SpecialistsOur Motorcycle Parts New Zealand Specialists StatementsMotorcycle Parts New Zealand Specialists for Dummies

Reach out to one of our experts today.CNC machining technology is rapidly ending up being the prime focus of several production procedures around the globe as a straight result of its several advantages over various other techniques. Additionally, the sectors that make motorcycles have jumped on board with this trend. The most innovative firms are now creating their engine elements and wheels making use of machining techniques originally established for motorcycle parts.

You might be wondering why we utilize. Currently that we have your attention allow us explain the reasoning behind this modern development in the bike manufacturing market.

Not known Facts About Motorcycle Parts New Zealand Specialists

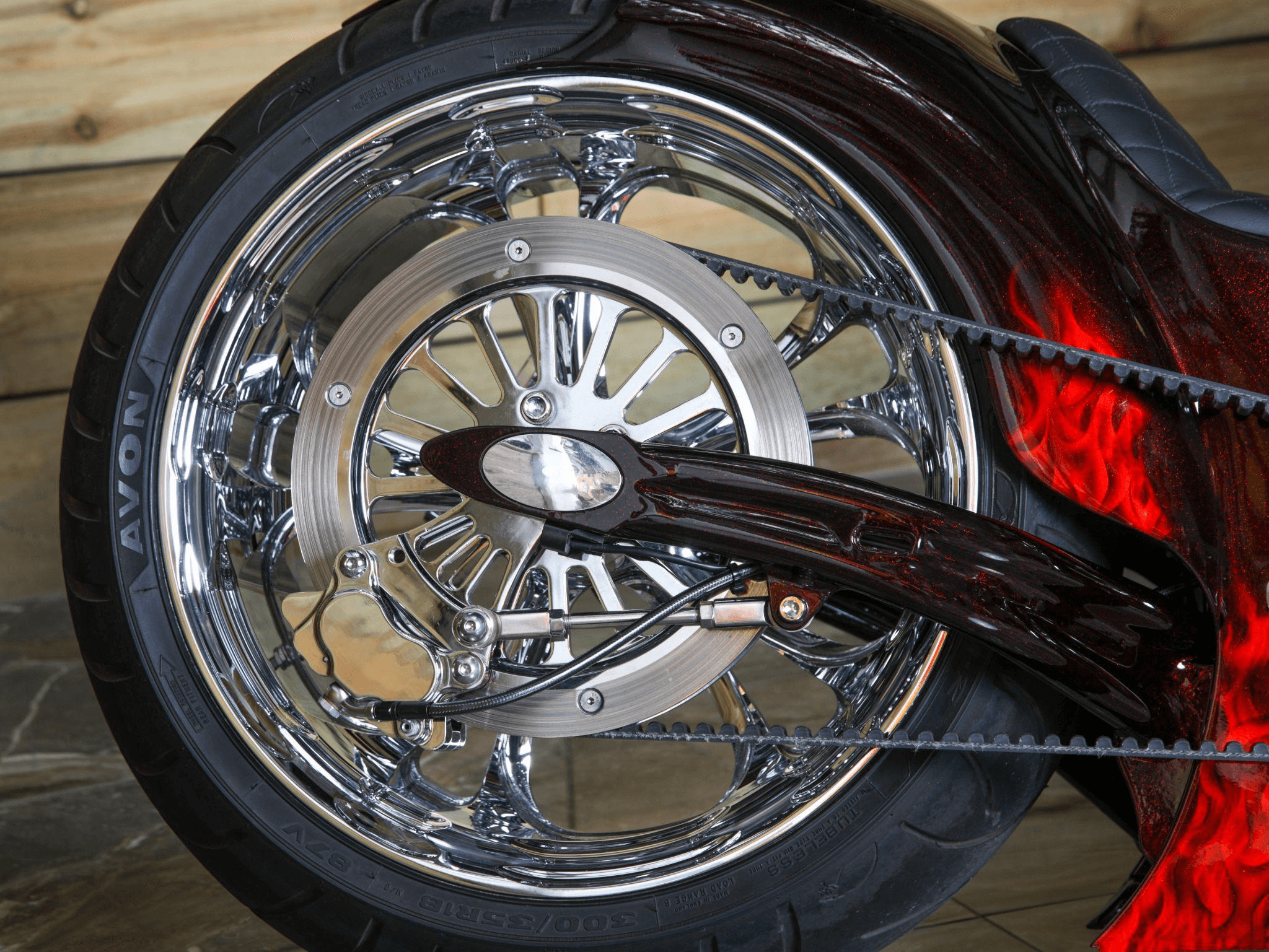

In addition, you have total control over the appearance of the components, also to the minute information. Sometimes, motorcyclists may decide to beautify their adventure by mounting aftermarket components or customizing the bike's transformation. Once again, computer mathematical control (CNC) machining is one of the most useful approach. Upgrades may be of any type of form and design you want.

Some Of Motorcycle Parts New Zealand Specialists

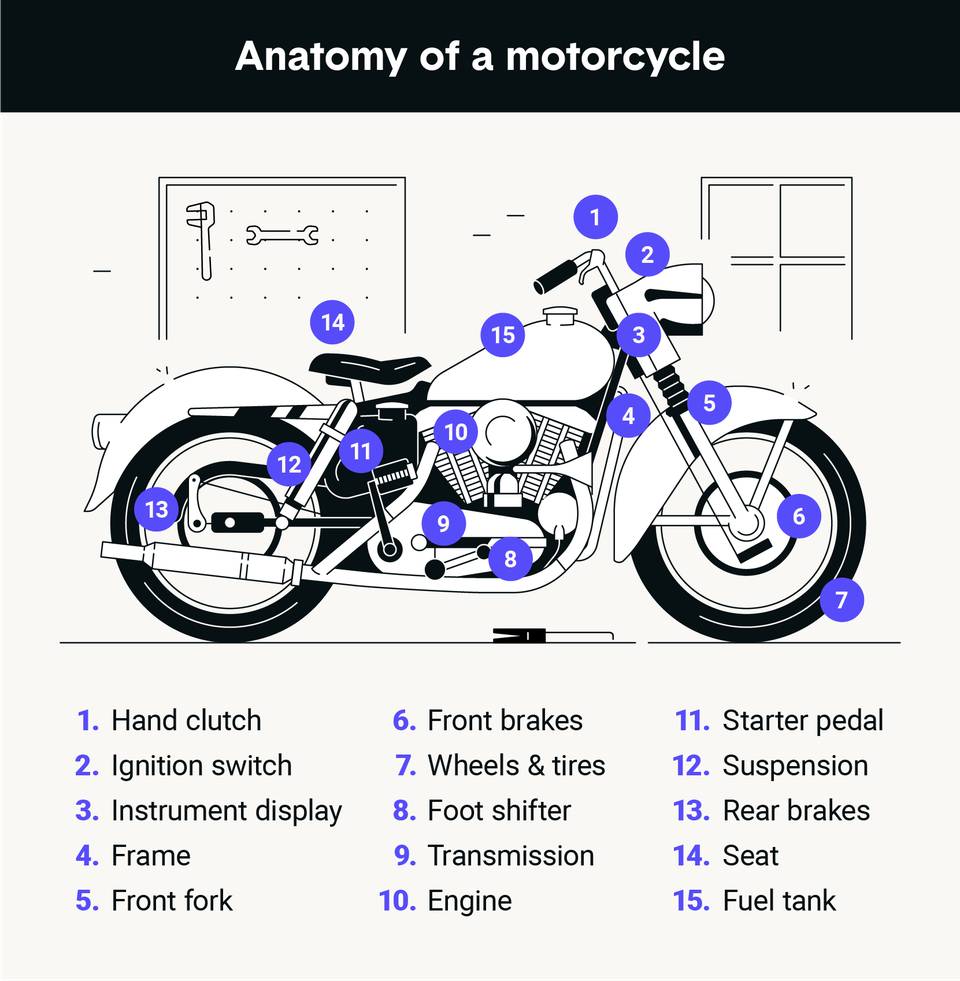

CNC machining may be made use of to make practically all of a motorbike's steel and plastic parts. To continue, we'll talk about several machined parts for motorbikes. As opposed to those on cars, wheels on bikes have a tendency to be extra apparent. Because of this, the bike's appearances might be boosted with the suitable customization of these wheels.

Milling treatments are used to acquire the preferred degree of wheel modification. An additional element of the bike that might be customized is the tires.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

When it concerns a car (or a motorbike), one of the most essential element is the engine. A number of people point to it as the "heart" of the vehicle. On the various other hand, the camshaft, the cyndrical tube head, and the pistons often tend to be complex and require designs with a high degree of precision.

Lighting is an additional facility element of modification. Use just top notch products, nonetheless, because these lights are important for the safety and security of motorcyclists and various other chauffeurs or individuals on the road, especially during the night. Motorcycle fronts lights have 3 main components: the bulb, or source of light, the lens, and the real estate. In particular, we tailor the lens and the real estate.

Milling processes with a remarkable coating would lead to the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not made up of delicate products; rather, it is created out of hard polymers that can be machined into even more complex patterns.

The Basic Principles Of Motorcycle Parts New Zealand Specialists

Bike producers commonly cast these components, yet only for the manufacturing of bespoke components. Machining on 5 axes in today's world is the ways by which any type of design form may be recognized.

Choose Runsom for your tailored motorcycle parts! We have the capacity to fabricate complex and trendy components making your bike matchless.

Below are a couple of examples of metals frequently made use of in motorcycle element machining. Light weight aluminum is the main material used by business focusing on generating customized bike components to develop the majority of these parts. In the past, we would certainly build our engines out of cast iron. On the various other hand, aluminum is promptly ending up being the product of choice, partly due to the fact that it is extra light-weight.

Zinc describes an additional steel that is extremely light in weight and has excellent machining qualities due to its high mechanical stamina. This product may be created right into nearly any type of shape and maintains its measurements well. Also mission-critical parts that need a high degree of precision might take advantage of their use.

The 5-Second Trick For Motorcycle Parts New Zealand Specialists

An additional steel that sees heavy use in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest steels that are now available and has excellent machinability attributes and toughness compatible with its low weight. One of the disadvantages of magnesium is that its dust might easily ignite.

Their most typical usage in creating different motorbike parts is fasteners, such as screws and screws. Their low vulnerability to oxidation and deterioration makes them optimal for this use.

5 Easy Facts About Motorcycle Parts New Zealand Specialists Described

It visit this website seems that CNC turning and grating are the fundamental processes. However, alternative strategies exist, such as boring. Allow's check out several of these machining strategies comprehensive. The CNC turning technique is thought about a subtractive manufacturing method. In addition, it requires maintaining bars of product, usually plastic or steel, ready and after that twisting a cutting tool to get rid of areas of the material as the product is turned.

These approaches are equally vital and produce elements with high precision and constant high quality. They are specifically: grinding, laser cutting, and exploration. The term "surface finish" describes post-processes after the first machining stage. Motorcycle Parts New Zealand Specialists. The processes assist boost the overall high quality of the machined motorbike components. Below are the short intro, benefits and drawbacks of 5 surface treatment methods.

Things about Motorcycle Parts New Zealand Specialists